Explore how the water sector is boosting efficiency, sustainability, accurate monitoring, predictive maintenance, and resilient management with Digital Twin Technology.

In recent years, the concept of Digital Twin technology has gained substantial traction across various industries, including healthcare, manufacturing, and more recently, water distribution. Water is an essential resource, and optimizing its distribution is crucial for sustainable management and ensuring reliable access. In the realm of digital twin technology, a noticeable global trend is the increasing enthusiasm for integrating IoT sensors with digital twins. The global digital twin market size was estimated at USD 16.75 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 35.7% from 2024 to 2030.

There is a growing emphasis on merging GIS data with digital twins to gain valuable spatial insights. Pioneering this innovation is Vassar Labs, offering a cutting-edge solution designed to revolutionize the water sector. This blog delves into the transformative impact of Digital Twin technology for water distribution optimization, spotlighting the advancements and promising future spearheaded by Vassar Labs.

Since the 1980s, global water use has risen by about 1% annually due to population growth, socio-economic development, and changing consumption patterns. This trend is expected to continue until 2050, resulting in a 20 to 30% increase in water demand, primarily driven by the industrial and domestic sectors.

At its core, a Digital Twin is a virtual replica of a physical system that utilizes real-time data, simulations, and advanced analytics to predict system behavior and outcomes. In the water sector, a Digital Twin can mimic the operational aspects of water distribution networks, providing utilities with invaluable insights into system performance and potential issues. This real-time mirroring allows for more precise monitoring, timely interventions, and well-informed decision-making processes .

Vassar Labs has innovated Digital Twin technology specifically tailored for enhancing water distribution systems. Their approach involves integrating high-resolution Earth observations and other data streams to create comprehensive simulations of the terrestrial water cycle. This offers a more granular understanding of water distribution dynamics, from source to faucet.

One of the significant applications of Vassar Labs’ Digital Twin technology is in utility management. By leveraging real-time data, utilities can identify inefficiencies, such as leakages or pressure anomalies, and mitigate them promptly. This real-time insight fosters a more resilient and adaptive infrastructure .

Such automation improves water utility operations by using real-time data analytics and advanced sensors for proactive infrastructure monitoring, enhancing task precision and efficiency, and promoting system reliability, resource conservation, and environmental sustainability.

Predictive maintenance is another profound application. Instead of conducting scheduled check-ups, utilities can use the Digital Twin to predict equipment failures ahead of time. This minimizes downtimes and reduces maintenance costs while enhancing service reliability.

In emergency scenarios, whether it be contamination events or natural disasters, Vassar Labs’ technology can simulate various response strategies, thereby aiding in swift and effective decision-making. This capability is vital for safeguarding public health and ensuring the system’s robustness .

By employing high-resolution simulations of the water cycle, Vassar Labs’ Digital Twin technology heralds a quantum leap in water management practices. With granular insights into water flow, consumption patterns, and potential stress points, utilities can build more resilient and sustainable water distribution networks.

One distinguishing feature of Vassar Labs’ approach is the use of high-resolution Earth observations. These observations provide unparalleled detail, revealing how water moves through different phases of the cycle. This comprehensive view is pivotal for crafting more accurate models of water systems, enabling utilities to refine their operations continuously.

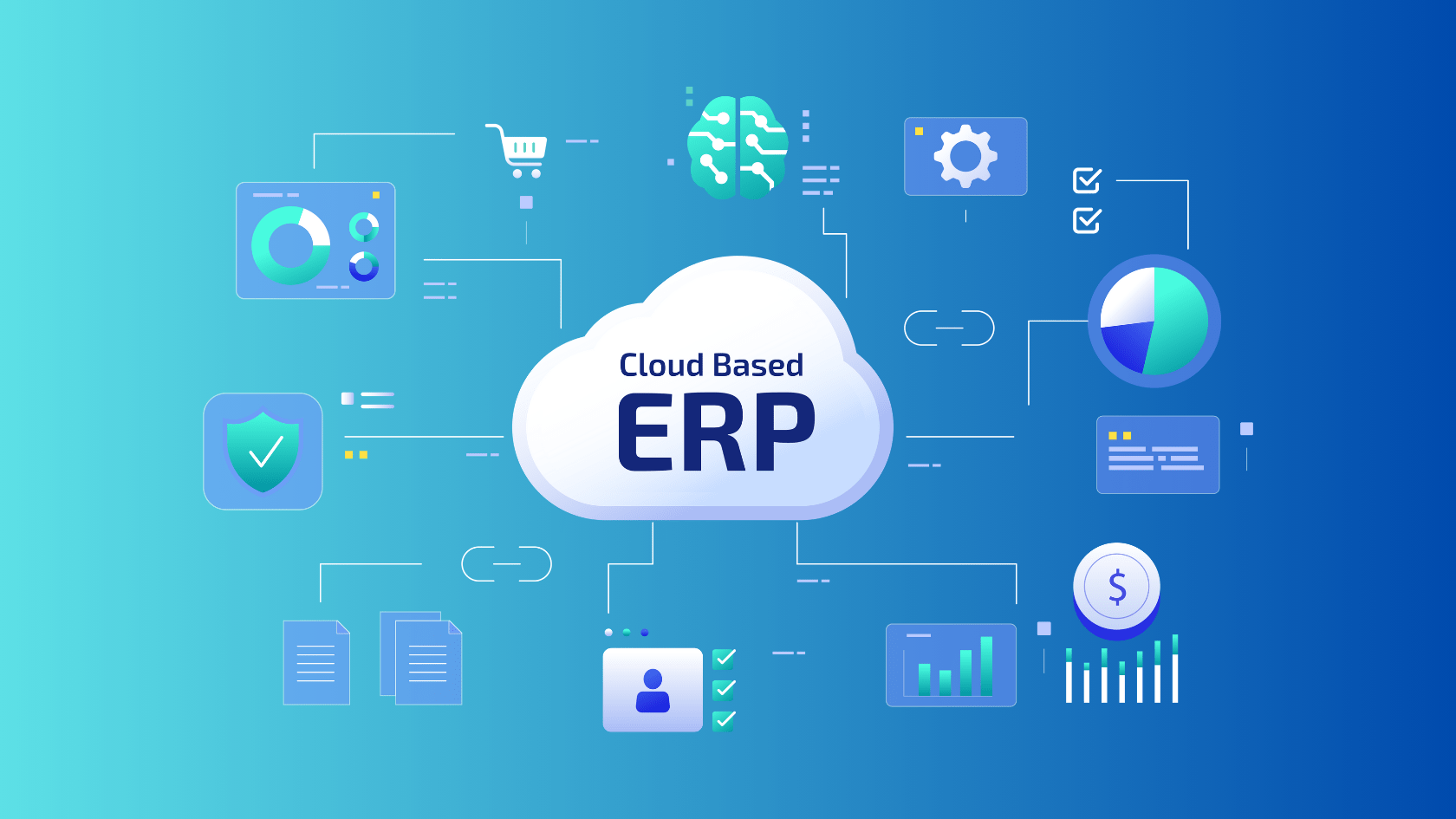

Vassar Labs’ advanced Digital Twin module introduces a unified, data-driven perspective of the water distribution network, assets, and operating situations. This module offers critical insights into the changing condition of water resources and equipment, allowing utilities to take corrective action proactively.

The module leverages IoT sensors placed throughout the transmission and distribution infrastructure, including pumping stations. This real-time data facilitates continuous KPI tracking, AI-driven optimization, scenario simulations, and key asset monitoring.

By integrating multiple data sources—SCADA, business, spatial, and non-spatial data—the module provides operational insights and visualizes real-time pressure and leakage information. It digitizes the distribution network into a GIS layer, making predictive maintenance possible with enhanced asset condition monitoring.

Real-time control and Digital Twin modeling within the module offer robust operational decision support. Periodically and automatically, the system reads current or historical data from exchange databases like SCADA, updates the hydraulic models, runs simulations, and provides results, including hydraulic decisions, alarms, and parameter settings .

d). Dynamic Planning and Problem Prediction:

Using dynamic planning based on demand from each node and supply availability, the system optimizes energy demands. It predicts potential problems through predefined or user-defined.

In conclusion, Digital Twin technology is transforming water distribution, enhancing efficiency, sustainability, and resilience. By using IoT sensors and high-resolution Earth observations for real-time insights, utilities can leverage predictive maintenance and improve emergency response. As water demand rises, Digital Twin technology is essential for creating robust, adaptive water management systems.